Dispensing Technologies in Automotive

During the manufacturing process, automobile manufacturers (automotive industry) use a lot of applications related to dispensing resins, adhesives, varnishes, foams, thermally conductive compounds, sealants, oils. In modern cars, the consumption of all kinds of adhesive and sealing materials is much higher than ever before. Therefore, it becomes expedient to use automated dispensing equipment. Starting with the simplest desktop dispenser and ending with a fully automated production dispensing line.

The use of automated dispensing systems makes it possible to influence production efficiency in the automotive segment. Such solutions ensure stability and accuracy, features that are particularly important when performing thousands of monotonous work cycles. In addition, automation of the process makes it possible to perform each production cycle at identical times.

Increasing the quality of manufactured products is a very valuable element in the automotive industry. Precise application of glue, in repeatable doses and proportions, performing the sealing process along a fixed and programmed path and many other dispensing processes are critically important elements of production in the automotive industry. Very often, many of the glued or sealed components are exposed to the external environment (rain, snow, sun) so only their precise bonding will guarantee extended trouble-free operation.

Modern, high-performance materials used in the process of joining and sealing automotive components are expensive, so minimizing waste is a very important issue. The size of the supplier’s packaging is also not insignificant. A larger container, such as a 200L barrel, is less burdensome to the environment than 10 buckets each of 20L. The use of a larger container often entails the need for professional equipment to collect the material nevertheless, in the end, the burden on the environment will be less and the purchase costs will be lower. Automobile production is a mass-scale operation, so even minimal amounts of savings will quickly balance the cost of the dispensing machine.

In summary, the main advantages of using automated dispensing equipment are as follows:

✔️ increasing production efficiency,

✔️ ensuring higher quality of products made,

✔️ minimizing waste.

which is brilliantly accomplished by automated dispensing systems.

Most common use of dispensing technology in the automotive industry:

💧 Dispensing of 2K adhesives or sealants occur on many automotive components, which translates into nearly 1% of the total vehicle weight. The use of usually quite expensive materials, such as those resistant to high temperatures and adverse conditions, requires precision, precisely measured dispensing and preparation of the mixture just before the application process. Adhesives and resin are also used for flooding and sealing automotive electronics. In such cases, the use of dedicated equipment with monitored process parameters is simply a necessity. An example of using a piston dispenser during the gluing process.

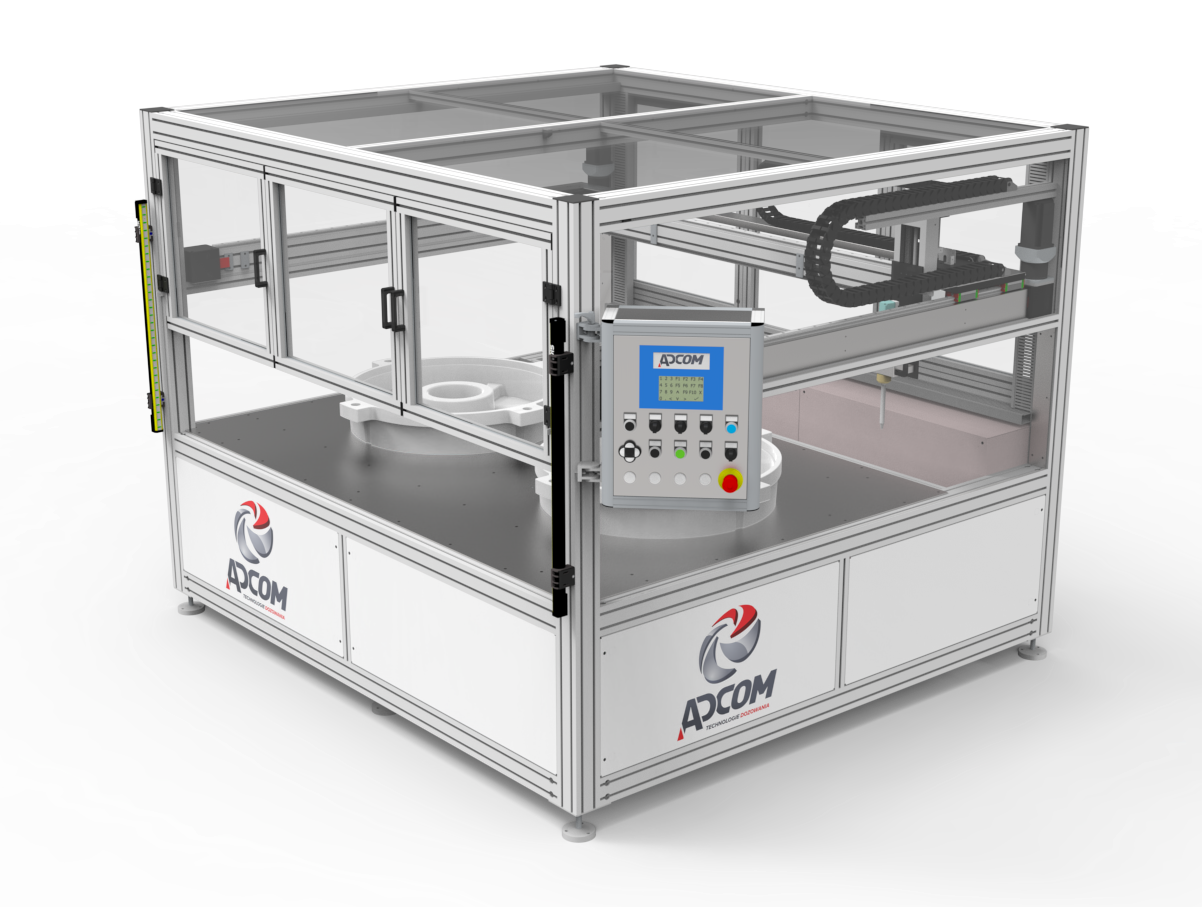

Example of a device used for dispensing adhesives and sealants

☔️ Dispensed gaskets – this is a technique that allows a perfect seal to be made directly on a component, so that the level of waste generated can be minimized. In the automotive industry, dispensed gaskets are most often used wherever there is a line (edge) of contact between the external environment and the vehicle’s accessories, such as in engine housings, transmission housings or exterior lighting components. An example of using an industrial robot to produce a cast gasket.

Example of a robot performing dispensing along a designated path

⚙️ Grease dispensing – dispensers and automated systems often also realize the process of dispensing grease. Components in cars that require the use of lubricants are all kinds of moving sections such as windshield wipers or locks. Lubricant not only affects the reduction of such factors as excessive friction, but also affects the auditory stimulus, the friction of the metal-on-metal structure is not exactly pleasant, and generates more wear on the mating parts.

Example of a device used for the grease dispensing process

🔥 Dispensing thermally conductive masses – is a process that allows, filling the void between the heat source element and the so-called heat sink that helps dissipate heat. It is most often used between two elements connected (twisted) to each other. In recent times when electric vehicles are becoming more and more popular, heat dissipation technology is very important. An additional requirement is the introduction of a strictly controlled amount of such material. With better thermal conductivity, the components have an increased service life and the risk of spontaneous combustion is minimized. Such a process also requires automation due to the rather unfavorable properties of the applied material.

Example of a robot performing dispensing of thermally conductive masses

Conclusion

The applications listed above are actually the most elementary cases. There are countless opportunities for automakers to use dispensing equipment. By modernizing production lines and using automatic dispensing systems, they can streamline the process and quickly amortize purchased machinery, resulting in savings for companies and the environment.